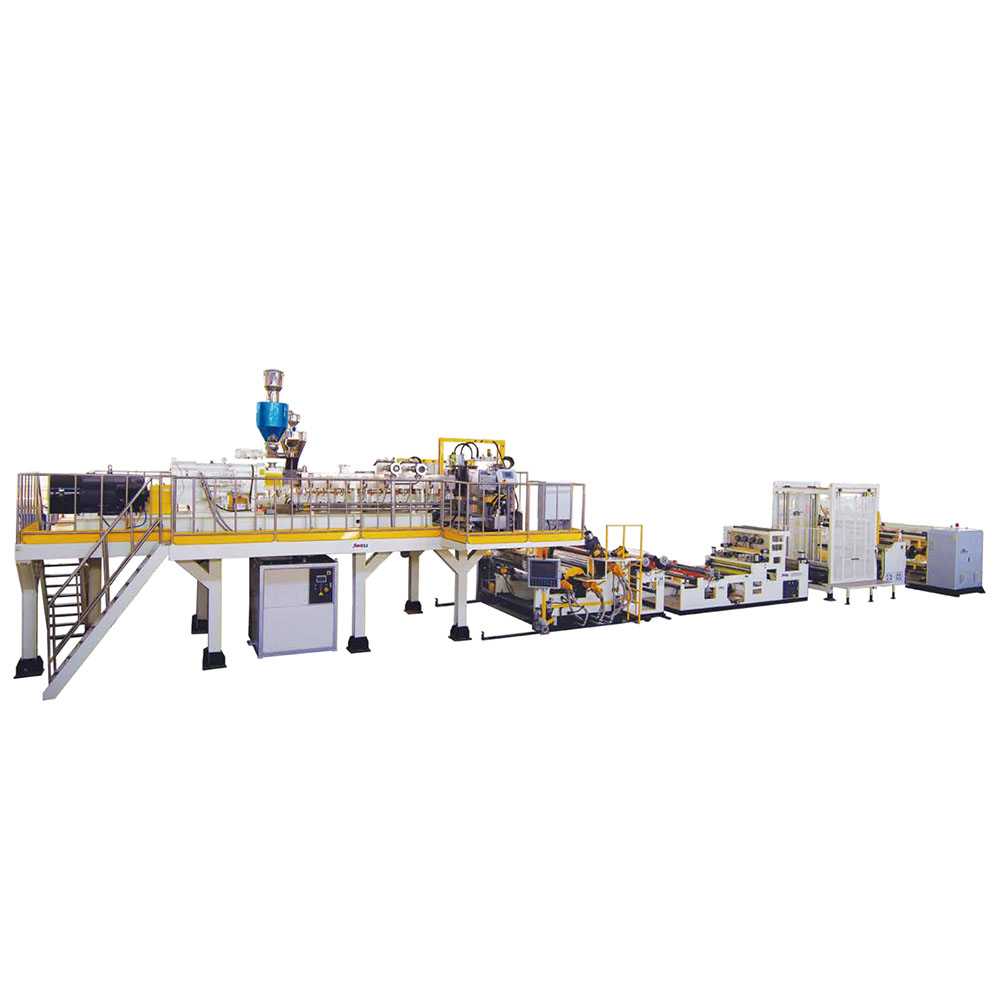

Professional Design Extrusion Film Process - PVC Foaming Board Extrusion Line – JWELL

Professional Design Extrusion Film Process - PVC Foaming Board Extrusion Line – JWELL Detail:

Product Presentation

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

The feature of PVC Semi-Skinning foam board

1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weight,heat preservation,sound insulation,shock absorption.

2.The process same with wood, but manufacturing performance is much better than wood.

Main technical parameter

| Model | tdgmodei | Products width(mm) | Products thickness (m) | Main motor power(k) | Max.Capacitz.1k,/h) |

| semi pigmented skin foamirg |

8]250/156 | i22o | 5-20 | 75 | 4oo |

| sj292/188 | 158o | 8-18 | 132 | 550 | |

| SJz92/188 | 2050 | 8-15 132 | 550 | ||

| Altotal of sgieezed foam |

sj280/156+sjz657132 | 192n | 5-20 75+37 | 500 | |

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Professional Design Extrusion Film Process - PVC Foaming Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Eindhoven, Adelaide, Mecca, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Write your message here and send it to us