Plastic Profile Extrusion

-

PVC High Speed Profile Extrusion Line

This line features stable plasticization, high output,low sheering force,long life service and other advantages. The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker.

-

WPC Door Frame Extrusion Line

The production line can produce the PVC wood-plastic door of the width between 600 and 1200 .the device has SJZ92/188 conical twin screw extruder, calibration, hall-off unit, cutter, such as stacker

-

WPC Wall Panel Extrusion Line

The machine is used for pollution WPC decoration product, which is widely used in house and public decoration field, features non-polution,

-

PVC Trunking Extrusion Line

PVC trunk is a kind of trunks, which is mainly used for internal wiring routing of electrical equipment. Now, environmentally friendly & flame retardant PVC trunk is widely used.

-

WPC Decking Extrusion Line

WPC (PE&PP)Wood-Plastic Floor is that the wood-plastic composite materials complete in different equipment of mixing, from play, extruding products, mixing the raw material in a certain formula, forming wood-plastic particles in the middle, and then squeezing out products.

-

PE Marine Pedal Extrusion Line

Traditional offshore culture in net cage mainly uses wooden net cage, wooden fishing raft and plastic foam.It will cause serious pollution to the sea area before and after the production and cultivation, and it’s also weak in resisting wind waves and resisting risks.

-

PS Foaming Frame Extrusion Line

YF Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker. This line with imported ABB AC inverter control, im- ported RKC temperature meter etc. and features of good plastification, high output capacity, and stable performance etc.

-

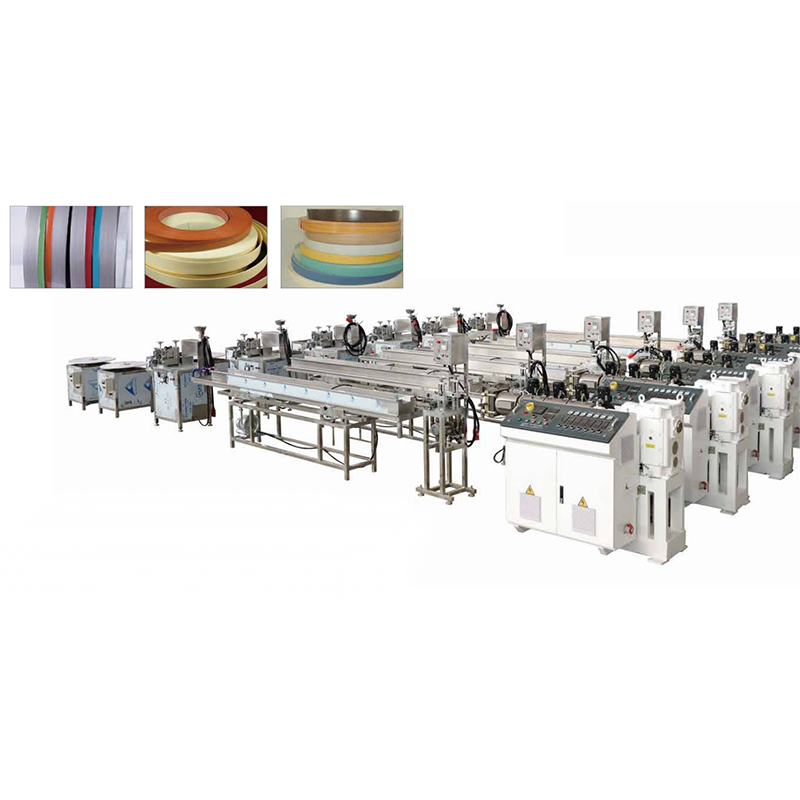

PVC Edge Banding Extrusion Line

Our company has absorbed the advanced technology at domestic and abroad and successfully developed the edge banding production line suitable for the needs of customers. The production line consists of single screw extruder or twin screw extruder and mold, embossing device,vacuum tank, haul-off unit as gluing roller device, air dryer device, cutting device, the winder device etc…

-

PVC/PP/PE/PC/ABS Small Profile Extrusion Line

By adopting the foreign and domestic advanced technology, we successfully developed the small profile extrusion line. This line consists of Single Screw Extruder, Vacuum Calibration Table, Haul-off Unit, Cutter and Stacker, the producing line features of good plasticization,

-

PP+CaCo3 Outdoor Furniture Extrusion Line

Outdoor furniture applications are increasingly widely, and traditional products are limited by their material itself, such as metal materials are heavy and corrodible, and wooden product are poor in weather resistance, in order to meet the market requirements, our newly developed PP with calcium powder as the main material of the imitation wooden panel products, it have been recognized by the market, and the market prospect is very considerable.

-

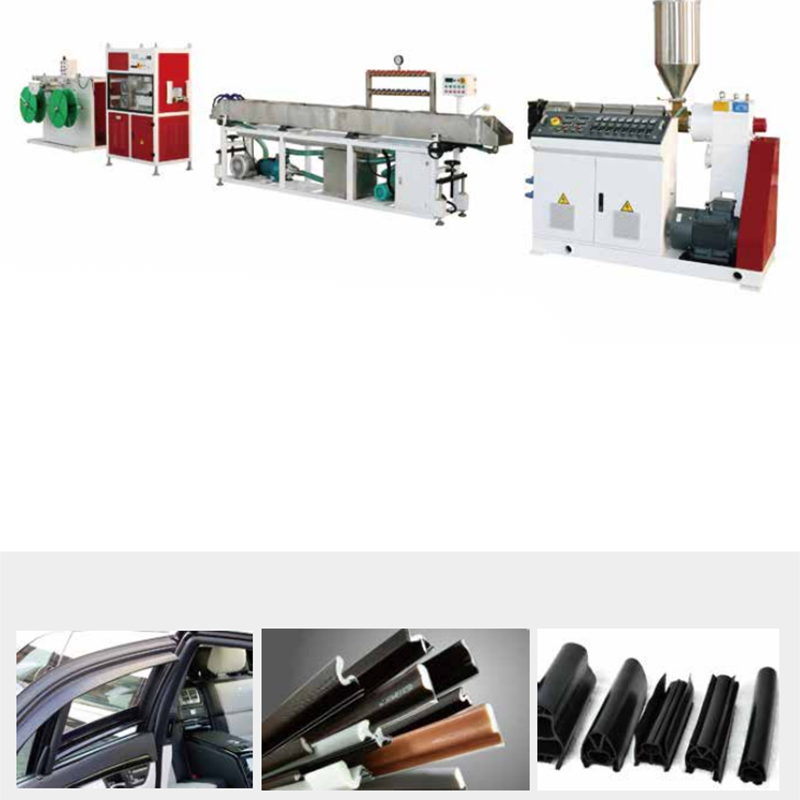

PVC/TPE/TPE Sealing Extrusion Line

The machine is used for producing sealing strip of PVC, TPU, TPE etc material, features high output, steady extrusion,

-

SPC Floor Extrusion Line

SPC Stone plastic extrusion line is PVC as base material and extruded by extruder,then get through four roll calendars,separately put PVC color film layer+PVC wear-resistance layer+PVC base membrane layer to be pressed and pasted together at one time progress.Simple process,complete the paste that depend on heat,without glue. SPC Stone-plastic environmental floor extrusion line advantage