18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL

18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL Detail:

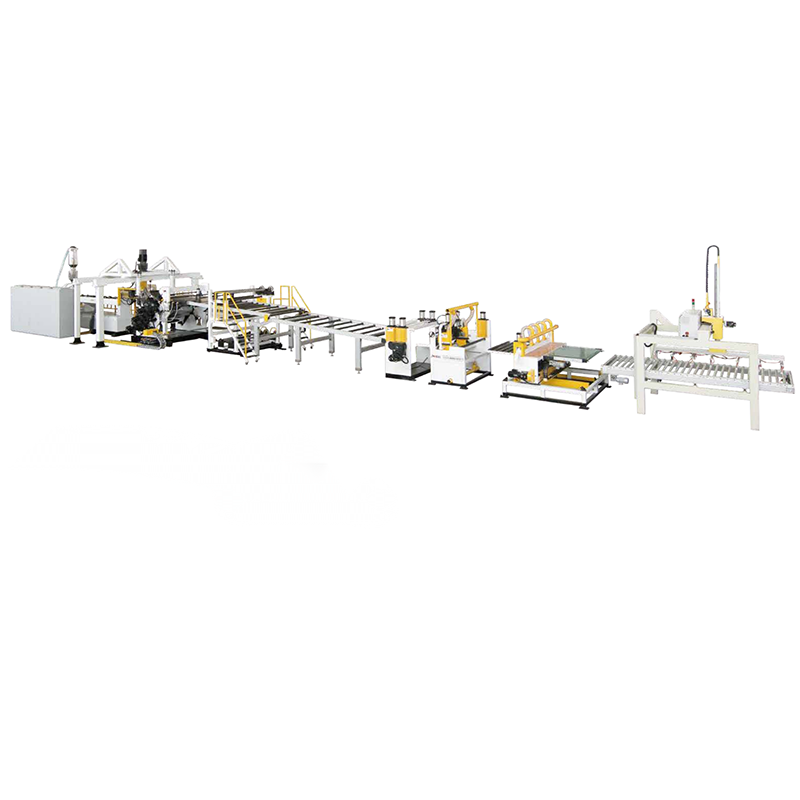

Product Presentation

Developed by Jwell company, this line is for producing multi-layer environmental-friendly sheet, which is widely used for vacuum forming, green food container and package, different kinds of food packaging container, such as: salver,bowl, canteen, fruit dish, etc.

Adopting maxim talc percentage in the sheet production, either customer will be able to reduce the cost of the sheet or increase the sheet degration character as well as gaining good physical properties and further processing abilities.

Main technical parameter

| Model | JWS150/120/90-1800 | JWS150/60-1200 | JWS130/60-1000 | JWS120-1000 | JWS100-800 |

| Width | 1500mm | 1000mm | 900mm | 800mm | 600mm |

| Thickness | 0.3-2mm | 0.3-2mm | 0.3-2mm | 0.2-2mm | 0.1-0.8mm |

| Capacity | 1000-1200kg/h | 700-800kg/h | 550-600kg/h | 400-

500kg/h |

300-350kg/h |

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for 18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL , The product will supply to all over the world, such as: Estonia, Mexico, Latvia, When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we're able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Write your message here and send it to us