Top Suppliers Plastic Extrusion Molding Process - PE Breathable Film Extrusion Line – JWELL

Top Suppliers Plastic Extrusion Molding Process - PE Breathable Film Extrusion Line – JWELL Detail:

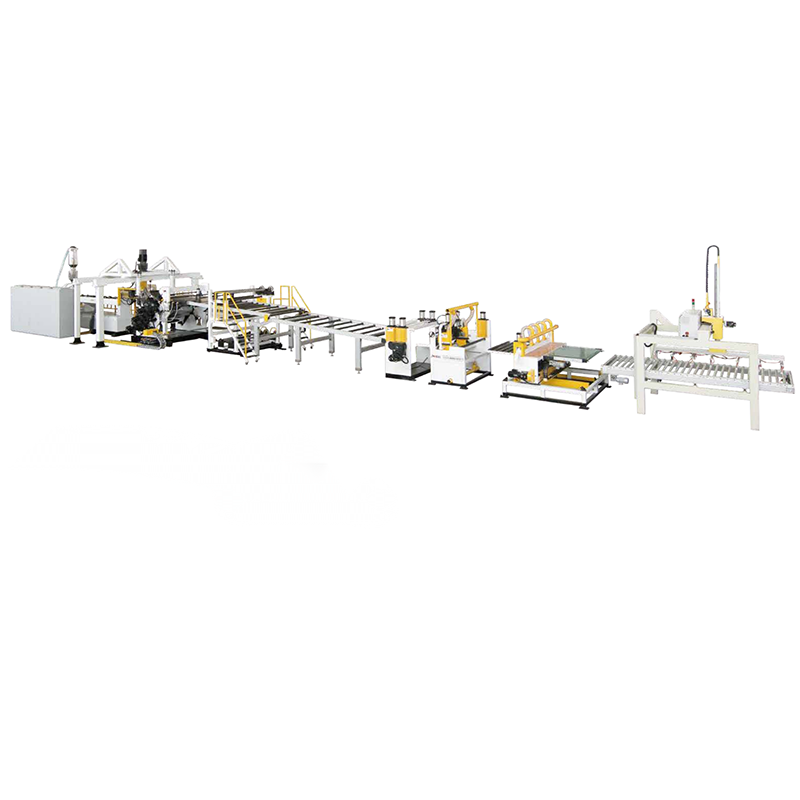

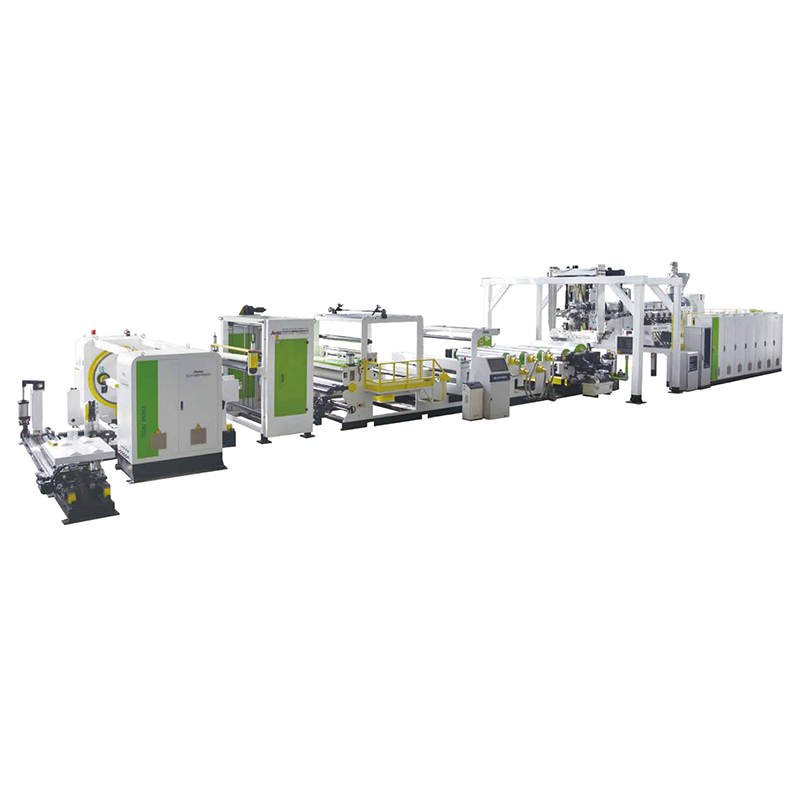

Product Presentation

The production line use PE air-permeable plastic granuels as raw material, and uses extrusion casting method to melt-extrude the PE-modified air-permeable plastic granuels containing inorganic filler through a flat die and the roller is stretched at a high rate to produce a sub-nanometer micro Porous membrane.

Main technical parameter

| Mode

JW130 |

Screw Diameter

130mm |

Materia

PE |

Products width

1600mm |

Capacity(Max.) 450-600kg/h | Main motor power

160KW |

| JW160 | 130mm | PE | 2200mm | 450-600kg/h | 200KW |

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Top Suppliers Plastic Extrusion Molding Process - PE Breathable Film Extrusion Line – JWELL , The product will supply to all over the world, such as: Honduras, New Orleans, Tunisia, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us