Quality Inspection for Sheet Extrusion Process - PVC Foaming Board Extrusion Line – JWELL

Quality Inspection for Sheet Extrusion Process - PVC Foaming Board Extrusion Line – JWELL Detail:

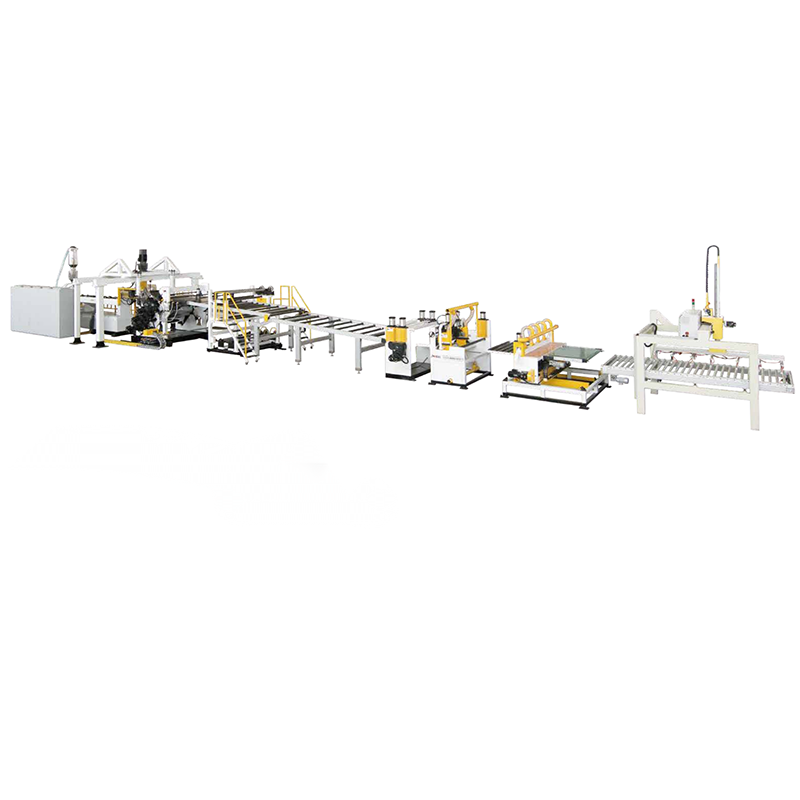

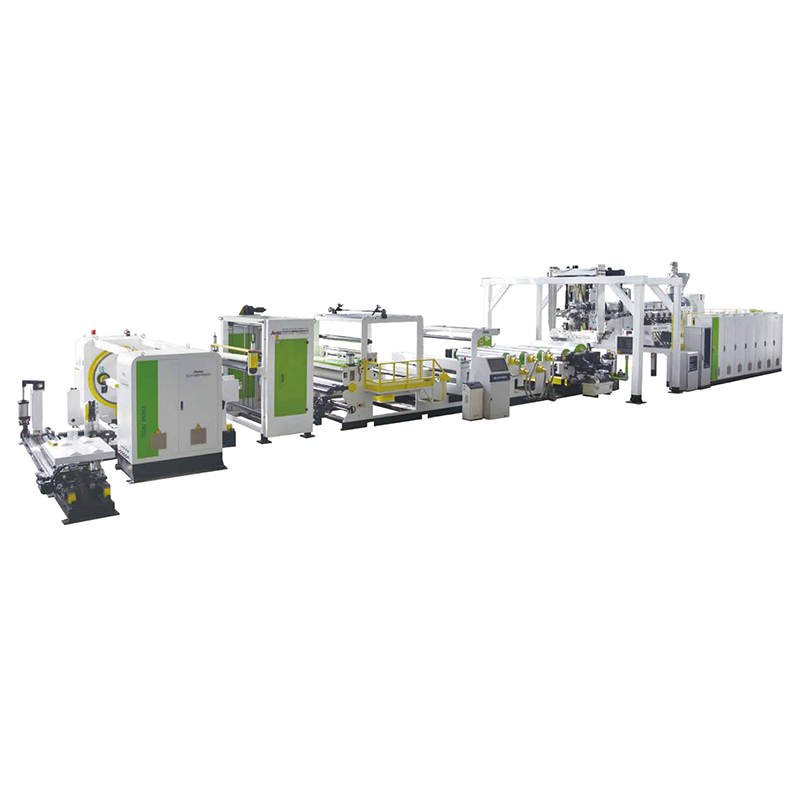

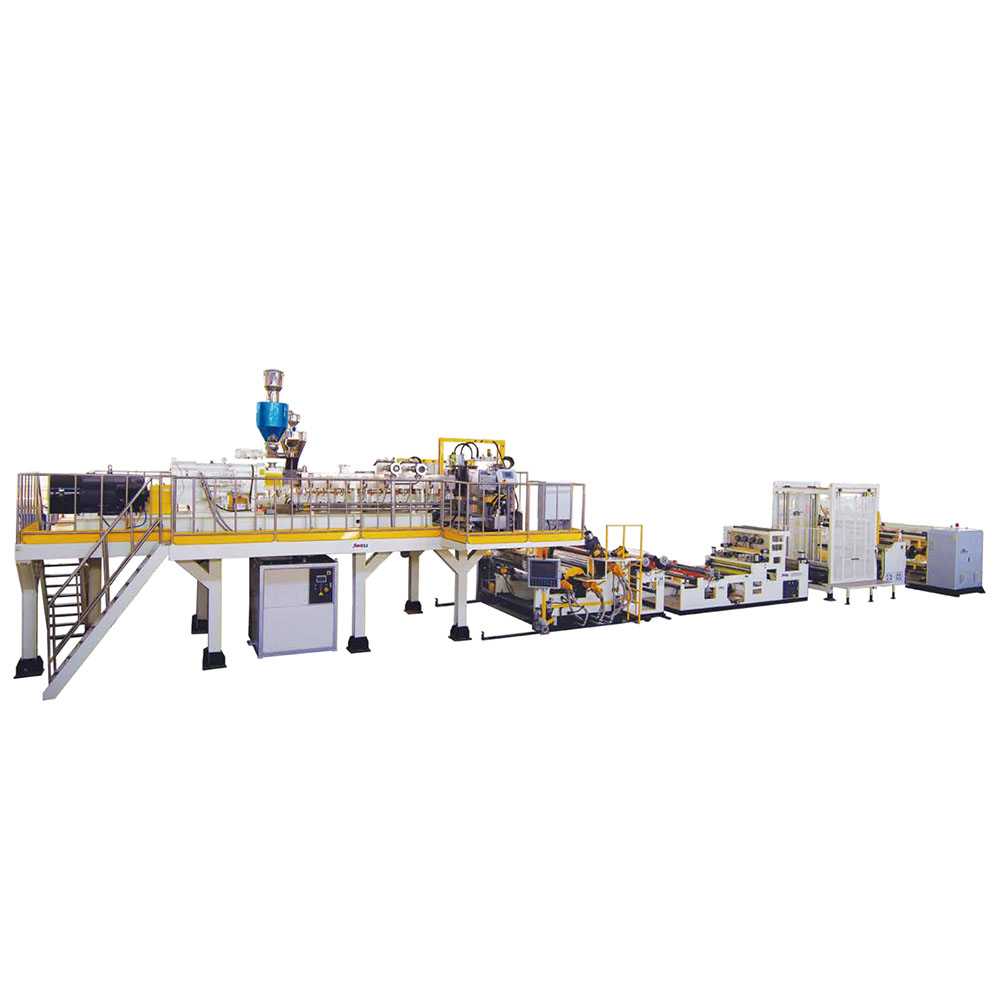

Product Presentation

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

The feature of PVC Semi-Skinning foam board

1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weight,heat preservation,sound insulation,shock absorption.

2.The process same with wood, but manufacturing performance is much better than wood.

Main technical parameter

| Model | tdgmodei | Products width(mm) | Products thickness (m) | Main motor power(k) | Max.Capacitz.1k,/h) |

| semi pigmented skin foamirg |

8]250/156 | i22o | 5-20 | 75 | 4oo |

| sj292/188 | 158o | 8-18 | 132 | 550 | |

| SJz92/188 | 2050 | 8-15 132 | 550 | ||

| Altotal of sgieezed foam |

sj280/156+sjz657132 | 192n | 5-20 75+37 | 500 | |

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for Quality Inspection for Sheet Extrusion Process - PVC Foaming Board Extrusion Line – JWELL , The product will supply to all over the world, such as: San Francisco, Adelaide, Plymouth, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Write your message here and send it to us