Products

-

PP/PE Solar Photovoltaic Cell Backsheet Extrusion Line

This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing;

-

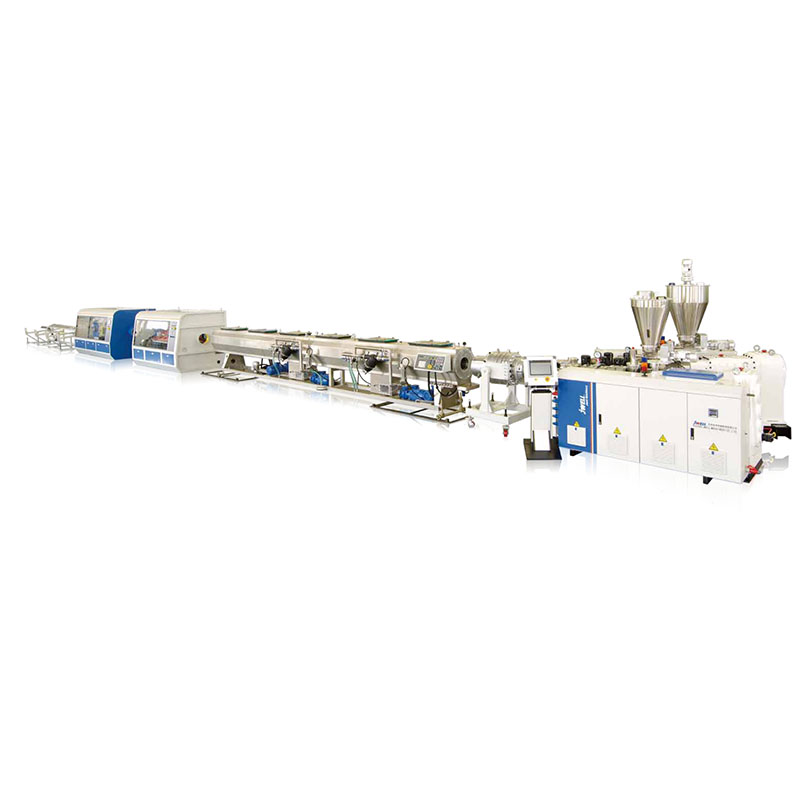

Three Layer PVC Pipe Co-extrusion line

Use two or more SJZ series conical twin screw extruder to implement co-extruded three-layer PVC pipe. The sandwich layer of the pipe is high-calcium PVC or PVC foam raw material.

-

WPC Wall Panel Extrusion Line

The machine is used for pollution WPC decoration product, which is widely used in house and public decoration field, features non-polution,

-

HDPE Heat Insulation Pipe Extrusion Line

PE insulation pipe is also called PE outer protection pipe, jacket pipe, sleeve pipe. The direct buried polyurethane insulation pipe is made of HDPE insulation pipe as the outer protective layer, the middle filled polyurethane rigid foam is used as the insulation material layer, and the inner layer is steel pipe. Polyure-thane direct buried insulation pipe has good mechanical properties and thermal insulation performance. Under normal circumstances, it can withstand high temperature of 120-180 °C, and is suitable for various cold and hot water high and low temperature pipeline insulation projects.

-

PC/PMMA/GPPS/ABS Sheet Extrusion Line

Garden, recreation place, decoration and the corridor pavilion; Internal and external ornaments in the commercial building, curtain wall of the modern urban building;

-

TPU Glass Interlayer Film Extrusion Line

TPU Glass Adhesive Film: As a new type of glass laminated film material, TPU has higher transparency, never yellowing, higher bonding strength to glass and more outstanding cold resistance.

-

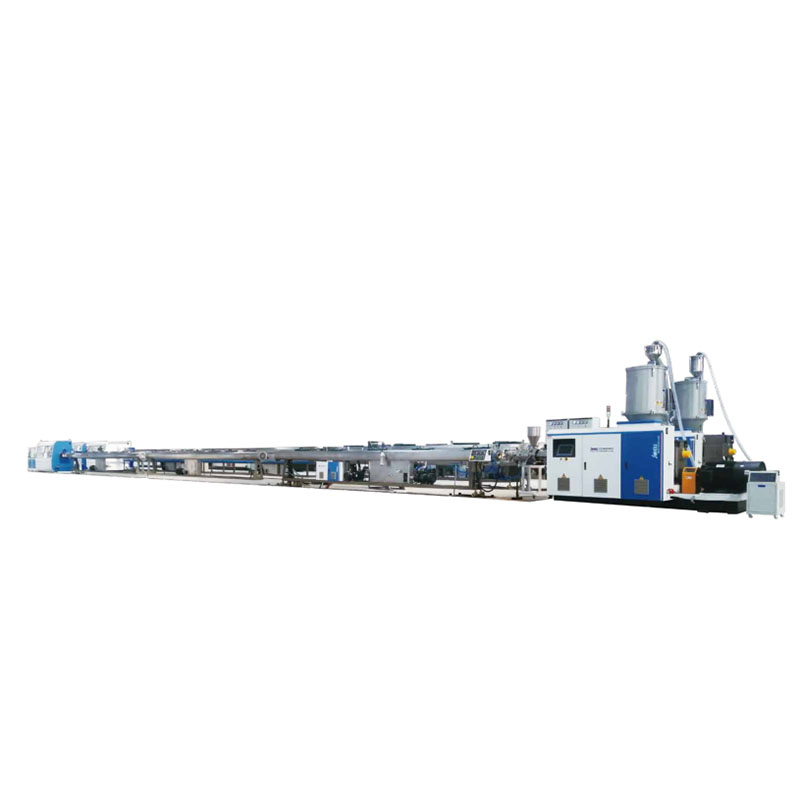

High-speed Energy-saving HDPE Pipe Extrusion Line

HDPE pipe is a type of flexible plastic pipe used for fluid and gas transfer and is often used to replace ageing concrete or steel mains pipelines. Made from the thermoplastic HDPE (high-density polyethylene), its high level of impermeability and strong molecular bond make it suitable for high pressure pipelines. HDPE pipe is used across the globe for applications such as water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit, and storm water and drainage pipes.

-

PVC Trunking Extrusion Line

PVC trunk is a kind of trunks, which is mainly used for internal wiring routing of electrical equipment. Now, environmentally friendly & flame retardant PVC trunk is widely used.

-

Silicon Coating Pipe Extrusion Line

The raw material of the silicon core tube substrate is high-density polyethylene, the inner layer used a lowest friction coefficient silica gel solid lubricant. It is corrosion resistance, smooth inner wall, convenient gas blowing cable transmission, and low construction cost. According to the needs, different sizes and colors of small tubes are concentrated by external casing. The products are applied to optical cable communication network system for freeway, railway and so on.

-

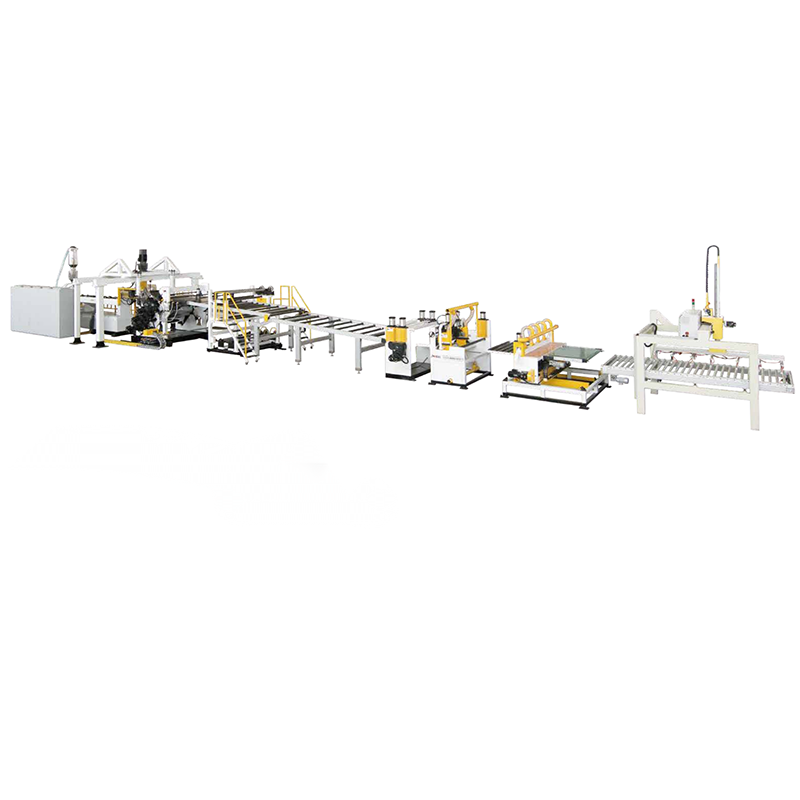

PP/PE/ABS/PVC Thick Board Extrusion Line

PP thick plate, is an environmentally-friendly product and is widely applied in chemistry industry, food industry, anti-erosion industry, environmentally-friendly equipments industry, etc.

PP thick plate extrusion line of 2000mm width is a newly developed line which is the most advanced and stable line compared with other competitors.

-

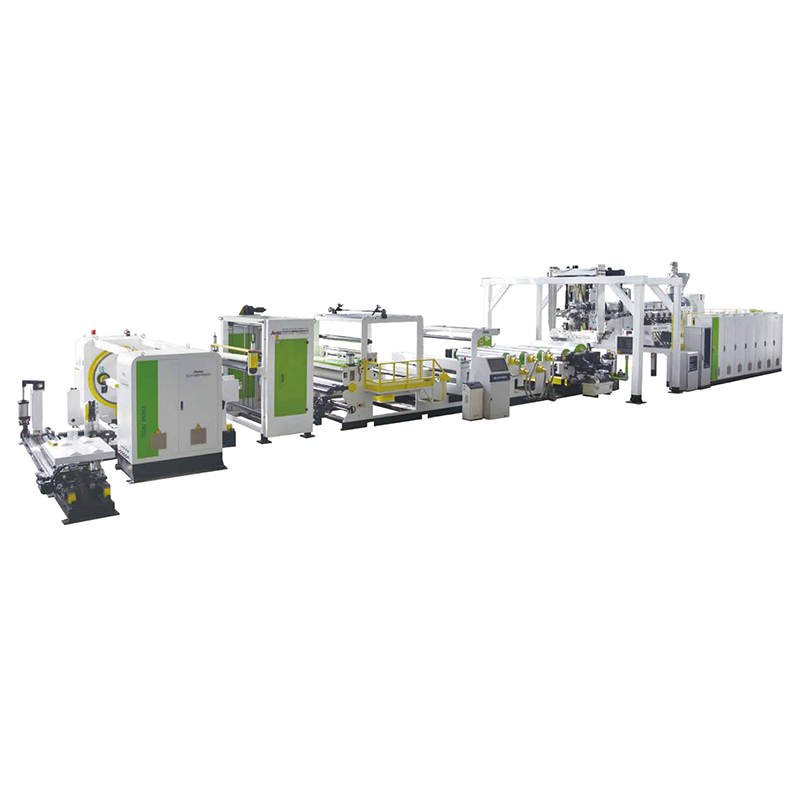

TPU Casting Composite Film Extrusion Line

TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattress, massage air bag, medical protection, industrial conveyor belt and professional waterproof backpack.

-

Multi-layer HDPE Pipe Co-extrusion Line

According to the special needs of users, we can provide 2-layer / 3-layer / 5-layer and multilayer solid wall pipe line. Multiple extruders can be synchronized, and multiple meter weight control system can be selected. can be centralize controlled in a main PLC to achieve precise and quantitative extrusion of each extruder. According to the multi-layer spiral mold designed with different layers and thickness ratios, the distribution of mold cavity flow channels is reasonable to ensure that the tube layer thickness is uniform and the plasticization effect of each layer is better.