Products

-

PP Honeycomb Board Extrusion Line

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board.

-

Stretch Film Extrusion Line

Stretch film production line is mainly used for PE lithium electric film; PP,PE breathable film; PP, PE, PET, PS thermo-shrinkage packing industrial. The equipment is composed by extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder and controlling system. Relying on our advanced designing and processing ability, our equipment’s features are:

-

PE Marine Pedal Extrusion Line

Traditional offshore culture in net cage mainly uses wooden net cage, wooden fishing raft and plastic foam.It will cause serious pollution to the sea area before and after the production and cultivation, and it’s also weak in resisting wind waves and resisting risks.

-

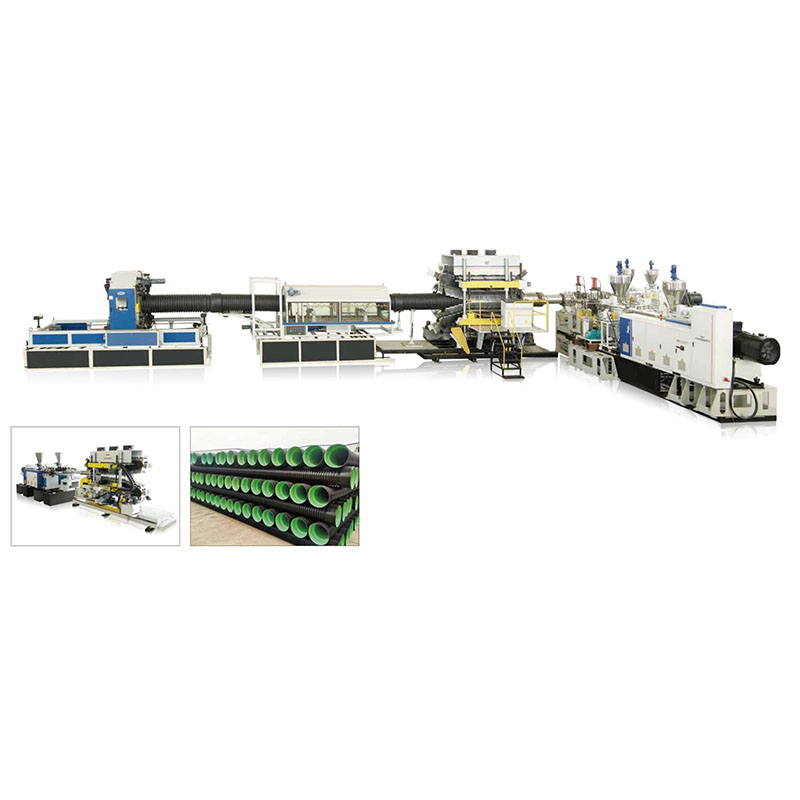

Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line

Suzhou Jwell introduced European advanced technology and newly developed parallel-parallel twin screw extruder HDPE/PP DWC pipe line.

-

PP/PE Hollow Cross Section Sheet Extrusion Line

The pp hollow cross section plate is light and high strength, moistureproof good environmental protection and re-fabrication performance.

-

PP/PE/PA/PETG/EVOH Multilayer Barrier Sheet Co-extrusion Line

Plastic packaging sheets are often used to produce disposable plastic cups, plates, bowls, dishes, boxes and other thermoforming products, which are widely used in the packaging of food, vegetables, fruits, beverages, dairy products, industrial parts and other fields. It has the advantages of softness, good transparency and easy to be made into popular styles of various shapes. Compared with glass, it is not easy to break, light in weight and convenient for transportation.

-

PVA Water Soluble Film Coating Production Line

The production line adopts one-step coating and drying method. The production line has high-speed automation, which reduces the production process, greatly reduces the production cost and improves the production efficiency.

The main components of the equipment are: dissolving reactor, precision T-die, support roller shaft, oven, precision steel strip, automatic winding and control system. Relying on our advanced overall design and processing and manufacturing capabilities, the core components are produced and processed independently.

-

PVB/SGP Glass Interlayer Film Extrusion Line

The building curtain wall, doors and windows are mainly made of dry laminated glass, which meets the above requirements. The organic glue layer material is mainly PVB film, and EVA film is rarely used. The new SGP film developed in recent years has excellent performance. SGP laminated glass has broad and good application prospects in glass skylights, glass exterior windows and curtain walls. SGP film is a laminated glass ionomer interlayer. The SGP ionomer interlayer produced by DuPont in the United States has excellent performance, the tear strength is 5 times that of ordinary PVB film, and the hardness is 30-100 times that of PVB film.

-

High Polymer Waterproof Rolls Extrusion Line

This product is used for waterproof protection projects such as roofs, basements, walls, toilets, pools, canals, subways, caves, highways, bridges, etc. It is a waterproof material with a wide range of uses and excellent performance. Hot-melt construction, cold-bonded. It can be used not only in the cold northeast and northwest regions, but also in the hot and humid southern regions. As a leak-free connection between the engineering foundation and the building, it is the first barrier to waterproofing the entire project and plays a vital role in the entire project.

-

EVA/POE Solar Film Extrusion Line

Solar EVA film, that is, solar cell encapsulation film (EVA) is a thermosetting adhesive film that is used to be placed in the middle of laminated glass.

Due to the superiority of EVA film in adhesion, durability, optical properties, etc., it is more and more widely used in current components and various optical products.