Plastic Pipe Extrusion

-

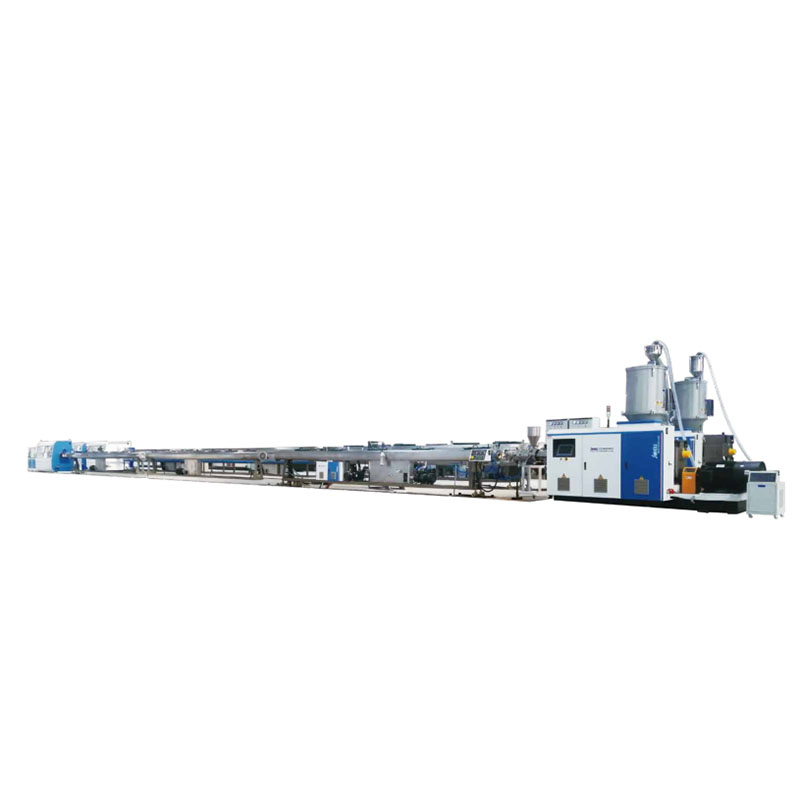

High-speed Energy-saving HDPE Pipe Extrusion Line

HDPE pipe is a type of flexible plastic pipe used for fluid and gas transfer and is often used to replace ageing concrete or steel mains pipelines. Made from the thermoplastic HDPE (high-density polyethylene), its high level of impermeability and strong molecular bond make it suitable for high pressure pipelines. HDPE pipe is used across the globe for applications such as water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit, and storm water and drainage pipes.

-

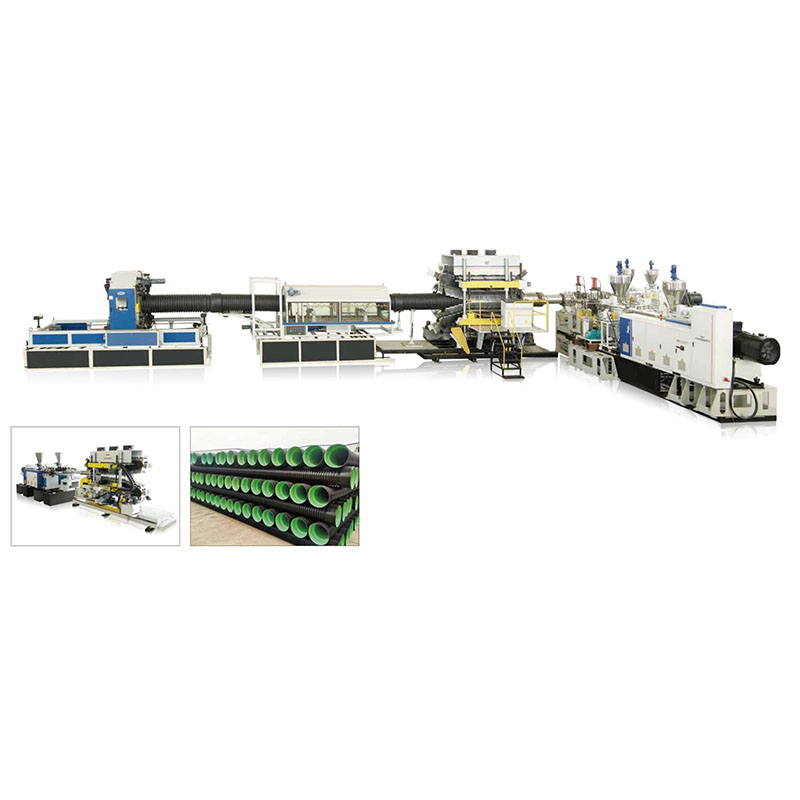

Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line

Suzhou Jwell introduced European advanced technology and newly developed parallel-parallel twin screw extruder HDPE/PP DWC pipe line.

-

Pressured Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.