Low MOQ for Extruder Pelletizer - PVC Foaming Board Extrusion Line – JWELL

Low MOQ for Extruder Pelletizer - PVC Foaming Board Extrusion Line – JWELL Detail:

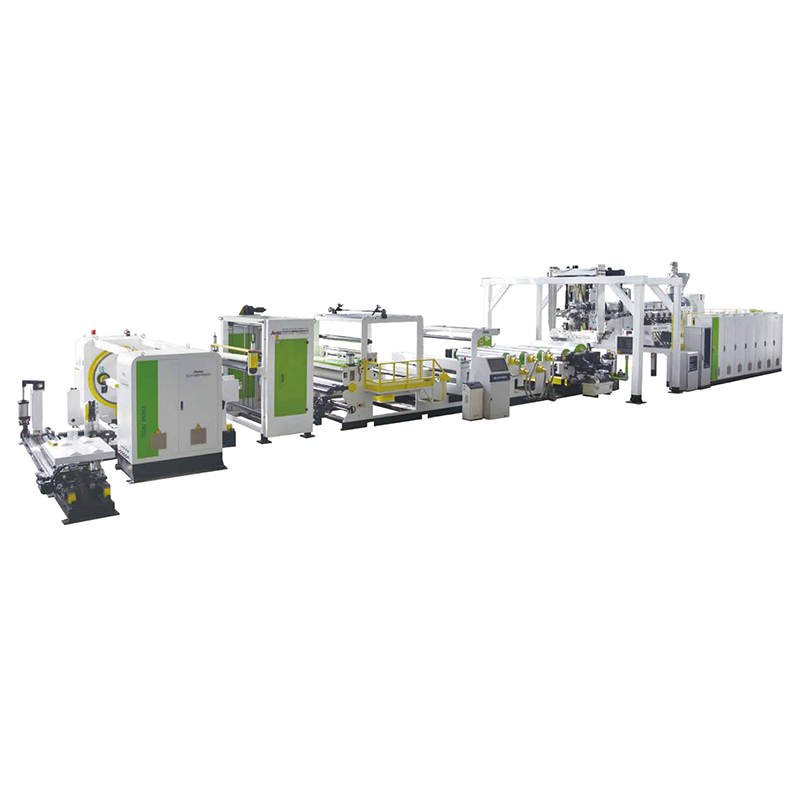

Product Presentation

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

The feature of PVC Semi-Skinning foam board

1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weight,heat preservation,sound insulation,shock absorption.

2.The process same with wood, but manufacturing performance is much better than wood.

Main technical parameter

| Model | tdgmodei | Products width(mm) | Products thickness (m) | Main motor power(k) | Max.Capacitz.1k,/h) |

| semi pigmented skin foamirg |

8]250/156 | i22o | 5-20 | 75 | 4oo |

| sj292/188 | 158o | 8-18 | 132 | 550 | |

| SJz92/188 | 2050 | 8-15 132 | 550 | ||

| Altotal of sgieezed foam |

sj280/156+sjz657132 | 192n | 5-20 75+37 | 500 | |

Product detail pictures:

Related Product Guide:

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for Low MOQ for Extruder Pelletizer - PVC Foaming Board Extrusion Line – JWELL , The product will supply to all over the world, such as: United States, Madras, Iran, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Write your message here and send it to us