Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL

Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL Detail:

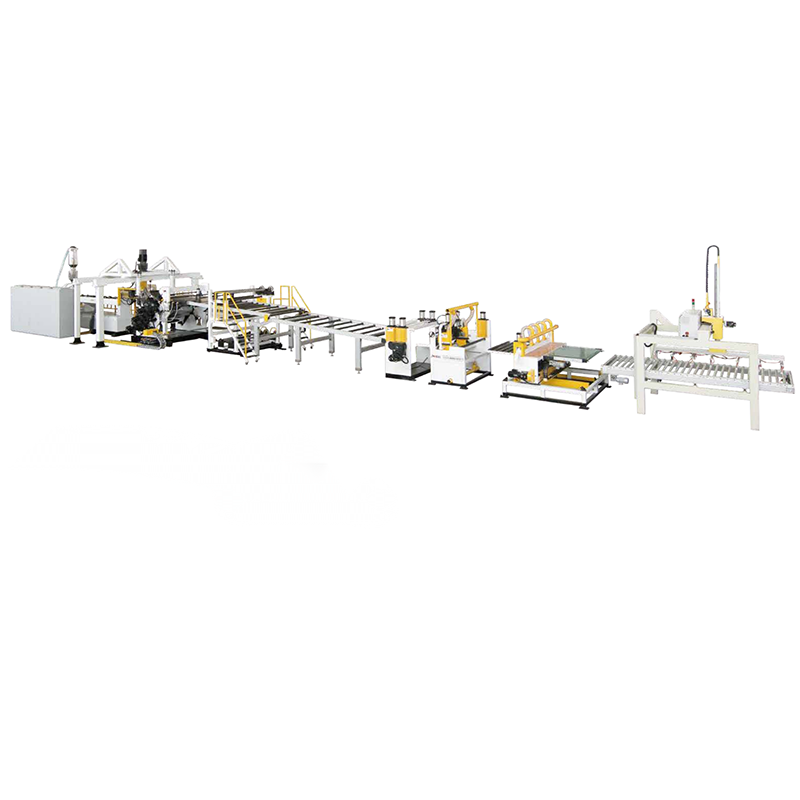

Product Presentation

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc.

Main technical parameter

| Mode | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h |

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth, will continue to serve outdated and new consumers from home and overseas whole-heatedly for Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Peru, Wellington, Belgium, With the principle of win-win, we hope to help you make more profits in the market. An opportunity is not to be caught, but to be created. Any trading companies or distributors from any countries are welcomed.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Write your message here and send it to us