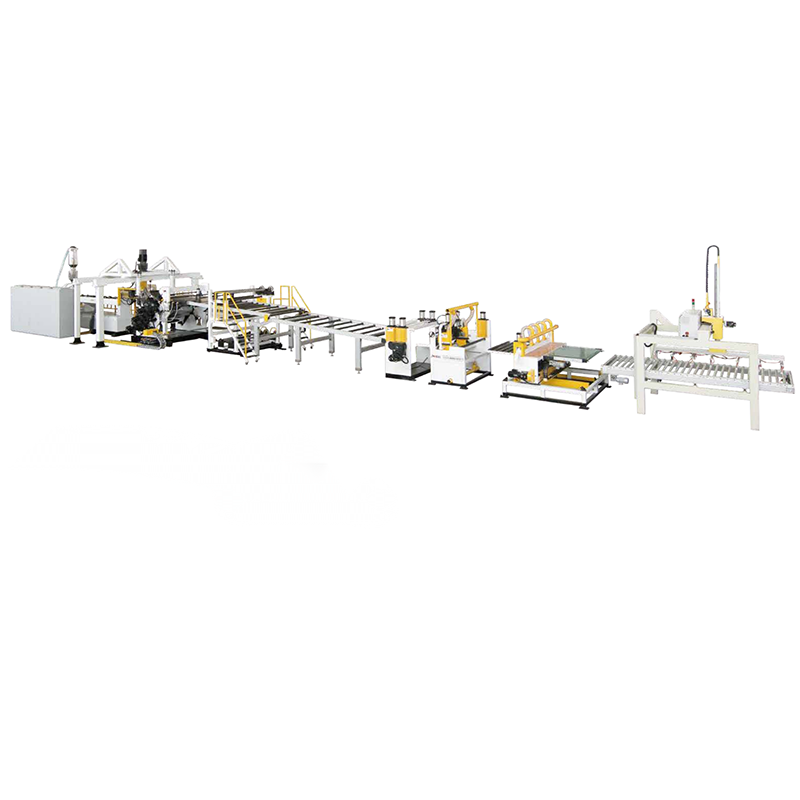

Factory Promotional Hdpe Extrusion Process - PVC Foaming Board Extrusion Line – JWELL

Factory Promotional Hdpe Extrusion Process - PVC Foaming Board Extrusion Line – JWELL Detail:

Product Presentation

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

The feature of PVC Semi-Skinning foam board

1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weight,heat preservation,sound insulation,shock absorption.

2.The process same with wood, but manufacturing performance is much better than wood.

Main technical parameter

| Model | tdgmodei | Products width(mm) | Products thickness (m) | Main motor power(k) | Max.Capacitz.1k,/h) |

| semi pigmented skin foamirg |

8]250/156 | i22o | 5-20 | 75 | 4oo |

| sj292/188 | 158o | 8-18 | 132 | 550 | |

| SJz92/188 | 2050 | 8-15 132 | 550 | ||

| Altotal of sgieezed foam |

sj280/156+sjz657132 | 192n | 5-20 75+37 | 500 | |

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Factory Promotional Hdpe Extrusion Process - PVC Foaming Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Brisbane, French, Bangkok, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Write your message here and send it to us