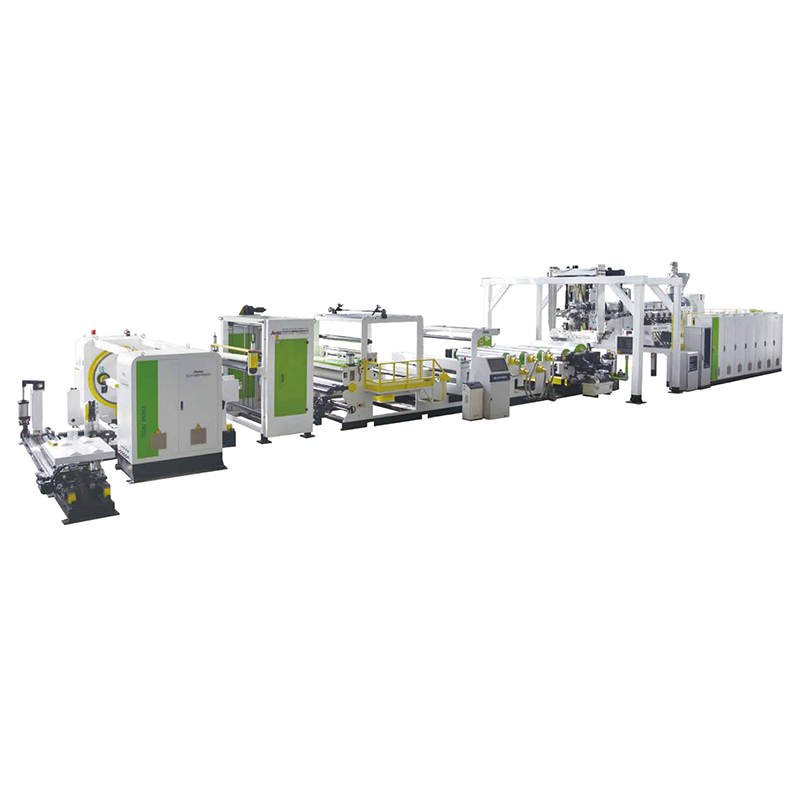

Factory directly supply Hdpe Pipe Extruder - High-speed Energy-saving MPP Pipe Extrusion Line – JWELL

Factory directly supply Hdpe Pipe Extruder - High-speed Energy-saving MPP Pipe Extrusion Line – JWELL Detail:

Main Technical Parameter

Performance & Advantages

1. MPP special 38D screw and screw groove feeding section, heat preservation cotton heating ring, low energy consumption while melt extrusion and plasticizing effect, and high torque reducer to ensure low noise operation and efficient output.

2. The extrusion mold is designed with special flow channel and added with air duct and double water ring sizing sleeve to ensure product quality and reduce cooling length.

3. 304 vacuum cooling tank controlled by frequency conversion, integrated water supply and drainage system, energy saving and noise reduction.

4. The servo driven multi track tractor can adapt to different pipe diameters with large speed regulation range.

5. High speed self centering chip free cutting machine, convenient and fast operation.

6. The precise meter weight control system reduces the requirements of the production line on the ability and quality of workers, saving energy and efficiency.

Advantages

1. MPP pipes have excellent electrical insulation.

2. MPP pipes have high heat distortion temperature and low temperature impact performance.

3. The tensile and compressive performance of MPP pipe is higher than that of HDPE.

4. MPP pipes are light, smooth, low friction resistance, and can be welded butt welded.

5. The long-term use temperature of MPP pipe is 5~70℃.

Usage

1. Municipal Engineering.

2. Telecom Engineering.

3. Power Engineering.

4. Gas engineering.

5. Water works.

6. Heating and other pipeline engineering.

Superiority

1. MPP electric power pipe has excellent electrical insulation.

2. MPP electric power pipe has high thermal deformation temperature and low temperature impact performance.

3. The tensile and compressive properties of MPP power pipe are higher than that of HDPE.

4. MPP electric power pipe is light and smooth, with small friction force, and can be butt welded by hot melting.

5. The long-term use temperature of MPP power pipe is – 5 ~ 70 ℃.

Instructions for construction

1. During the transportation and construction of MPP electric power pipe, it is strictly prohibited to throw, impact, carve and expose.

2. When the MPP pipe is butt welded, the axis of the two pipes shall be aligned and the end face shall be cut vertically and flat.

3. The processing temperature, time, pressure of MPP pipe shall be adjusted according to the climatic conditions.

4. The minimum bending radius of MPP electric power pipe shall be ≥ 75 pipe outer diameter.

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Factory directly supply Hdpe Pipe Extruder - High-speed Energy-saving MPP Pipe Extrusion Line – JWELL , The product will supply to all over the world, such as: Lisbon, Israel, South Africa, In order to carry out our goal of customer first and mutual benefit in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!