China OEM Extruder Equipment - PVC Foaming Board Extrusion Line – JWELL

China OEM Extruder Equipment - PVC Foaming Board Extrusion Line – JWELL Detail:

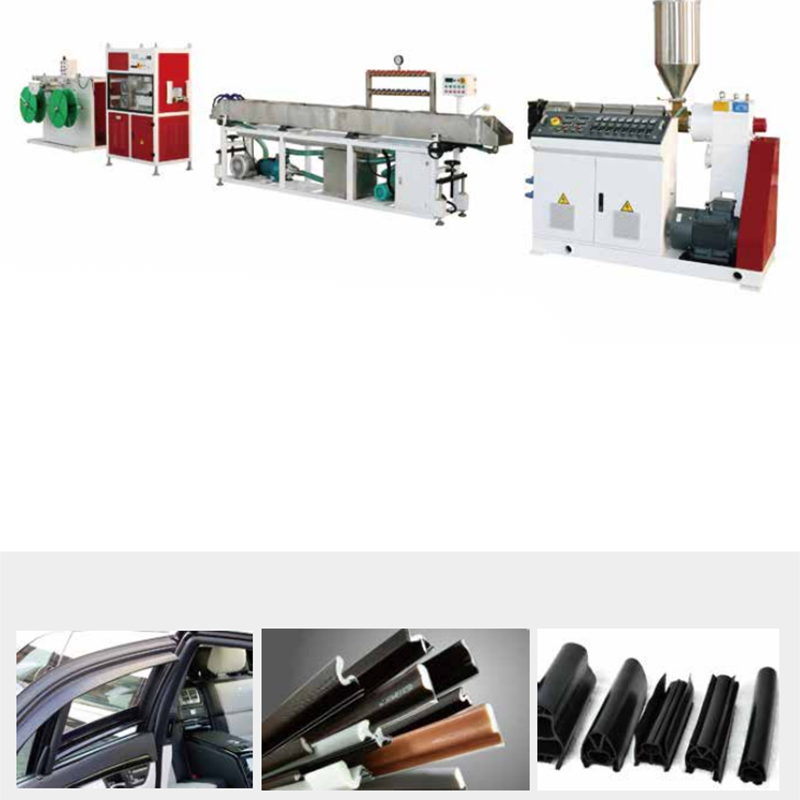

Product Presentation

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

The feature of PVC Semi-Skinning foam board

1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weight,heat preservation,sound insulation,shock absorption.

2.The process same with wood, but manufacturing performance is much better than wood.

Main technical parameter

| Model | tdgmodei | Products width(mm) | Products thickness (m) | Main motor power(k) | Max.Capacitz.1k,/h) |

| semi pigmented skin foamirg |

8]250/156 | i22o | 5-20 | 75 | 4oo |

| sj292/188 | 158o | 8-18 | 132 | 550 | |

| SJz92/188 | 2050 | 8-15 132 | 550 | ||

| Altotal of sgieezed foam |

sj280/156+sjz657132 | 192n | 5-20 75+37 | 500 | |

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for China OEM Extruder Equipment - PVC Foaming Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Algeria, Serbia, Singapore, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

Write your message here and send it to us