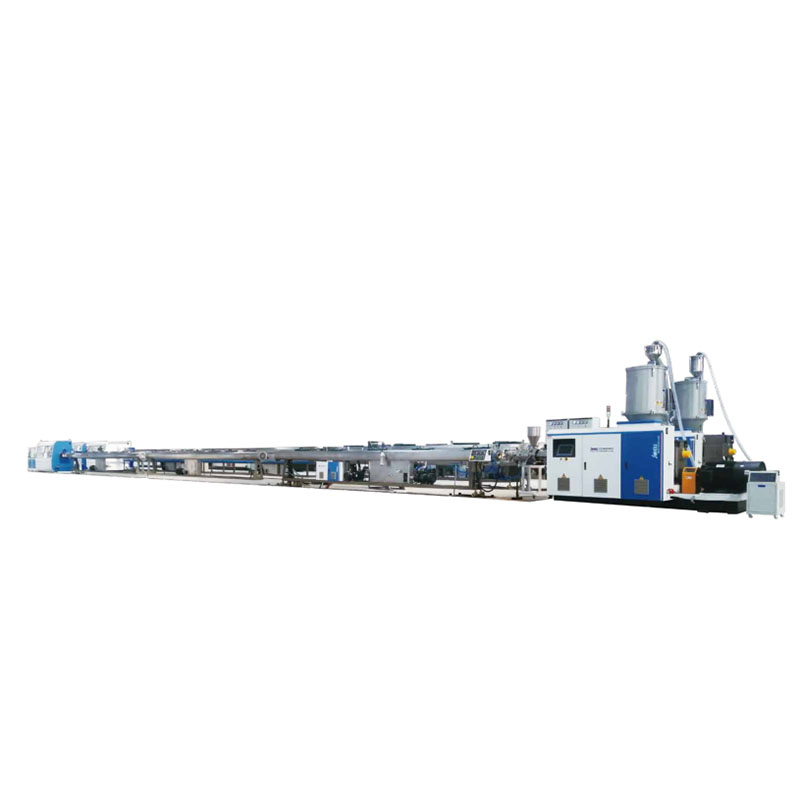

Cheapest Factory Hdpe Pipe Extrusion Process - High-speed Single Screw HDPE/PP DWC Pipe Extrusion Line – JWELL

Cheapest Factory Hdpe Pipe Extrusion Process - High-speed Single Screw HDPE/PP DWC Pipe Extrusion Line – JWELL Detail:

Main Technical Parameter

| Type | Pipe diameter | HDPE output | Max speed(m/min) | Total power |

| JWSBL-300 | 110-300 | 500 | 5.0 | 440 |

| JWSBL-600 | 200-600 | 800 | 5.0 | 500 |

| JWSBL-800 | 200-800 | 1000 | 3.0 | 680 |

| JWSBL-1000 | 200-1000 | 1200 | 2.5 | 710 |

| JWSBL-1200 | 800-1200 | 1400 | 1.5 | 800 |

Note:The specifications are subject to change without prior notice.

Performance & Advantages

1. The newly designed closed molding machine adopts a special high-efficiency cooling system for forming aluminum modules, which greatly improves the cooling efficiency in the production of corrugated pipe products.

2. High-speed, high-output single-screw extrusion machine supporting a professional design of the corrugated pipe extrusion mould to achieve large-scale stable extrusion.

3. Good interchangeability of the module; the aluminum forming module uses LY12 high-quality alloy aviation aluminum material with copper content ≥ 5%, precision pressure casting process, high density material, no light pores, long-term use is not easily deformed. Can customize various module waveform schemes according to the user’s requirements.

4. Supporting automatic DWC cutter, computer control, accurate cutting position, stable running and easy to operate.

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

B- Spiral Corrugated Pipes – Steel Reinforced Corrugated Pipes:

Spiral Corrugated Pipes – Steel Reinforced Corrugated Pipe is produced by HDPE raw materials and usually known as larger diameters (diameters of 500 mm and above) are preferred for. In the welding of Corrugated Spiral Pipes combined by electrofusion coupler method therefore once assembled with tightness level reached a maximum and doesn’t disperse on. Spiral Corrugated Pipes – Steel Reinforced Corrugated Pipe are using even if the terrain is gravelly which will be laid is prevent fracture due to the resiliency. The lenghts are usually produced as 6 meters and 7 meters of Spiral Corrugated Pipes – Steel Reinforced Corrugated Pipe. However, in order to provide advantages in transportation costs in the local shipments 14 meters and produced 13.5 meters for abroad and the vehicles are loaded with the maximum volume for take optimum loadings.

Fields of Use

Steel Reinforced Corrugated Pipes are mainly used in:

● Drainage pipeline.

● Big airports underground infrastructure projects.

● Sub-railway passage projects.

● Stadium sewage network projects.

● Big irrigation pipeline projects.

● City sewage network projects.

● Storm water discharge projects.

● Discharge of underground water projects to produce big manholes.

Product detail pictures:

Related Product Guide:

Adhering to the principle of quality, service, efficiency and growth, we have gained trusts and praises from domestic and international client for Cheapest Factory Hdpe Pipe Extrusion Process - High-speed Single Screw HDPE/PP DWC Pipe Extrusion Line – JWELL , The product will supply to all over the world, such as: Grenada, Mexico, Amsterdam, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.