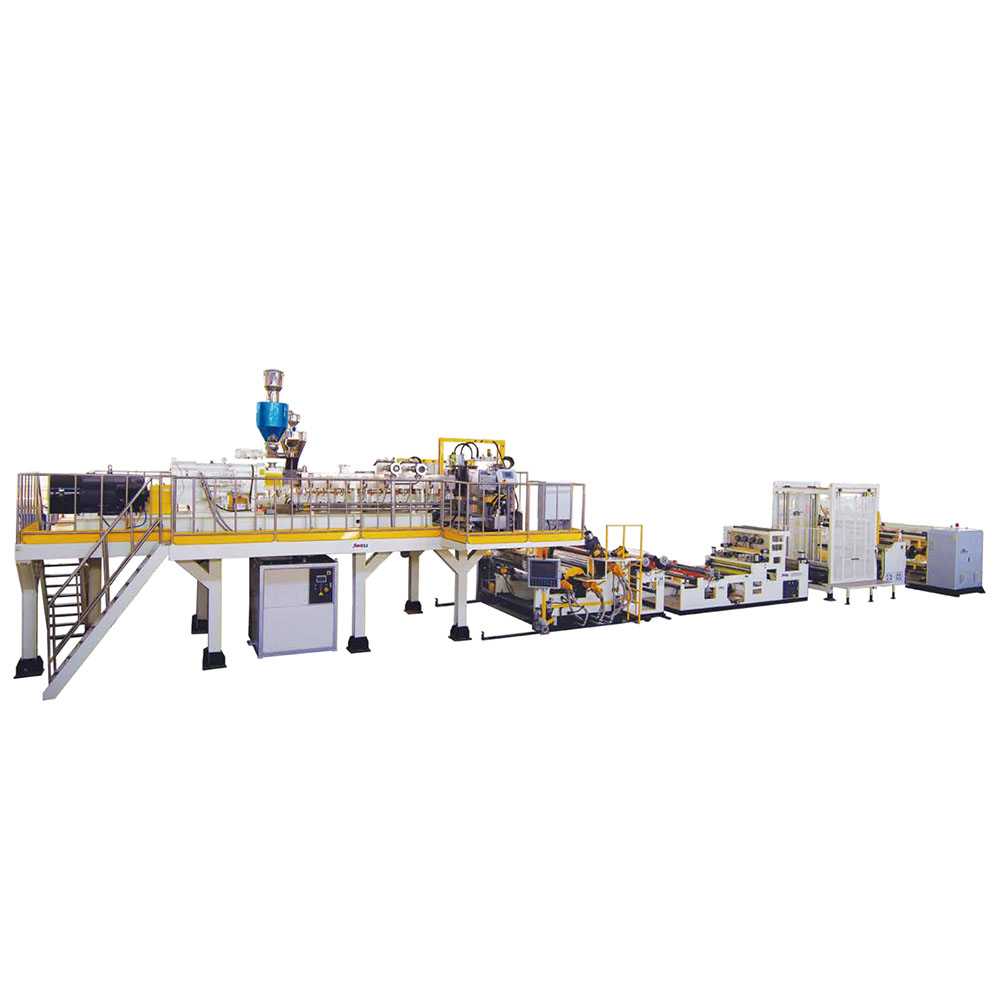

Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL

Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL Detail:

Product Presentation

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc.

Main technical parameter

| Mode | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h |

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of Quality, Performance, Innovation and Integrity. We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Jersey, French, Kazakhstan, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Write your message here and send it to us