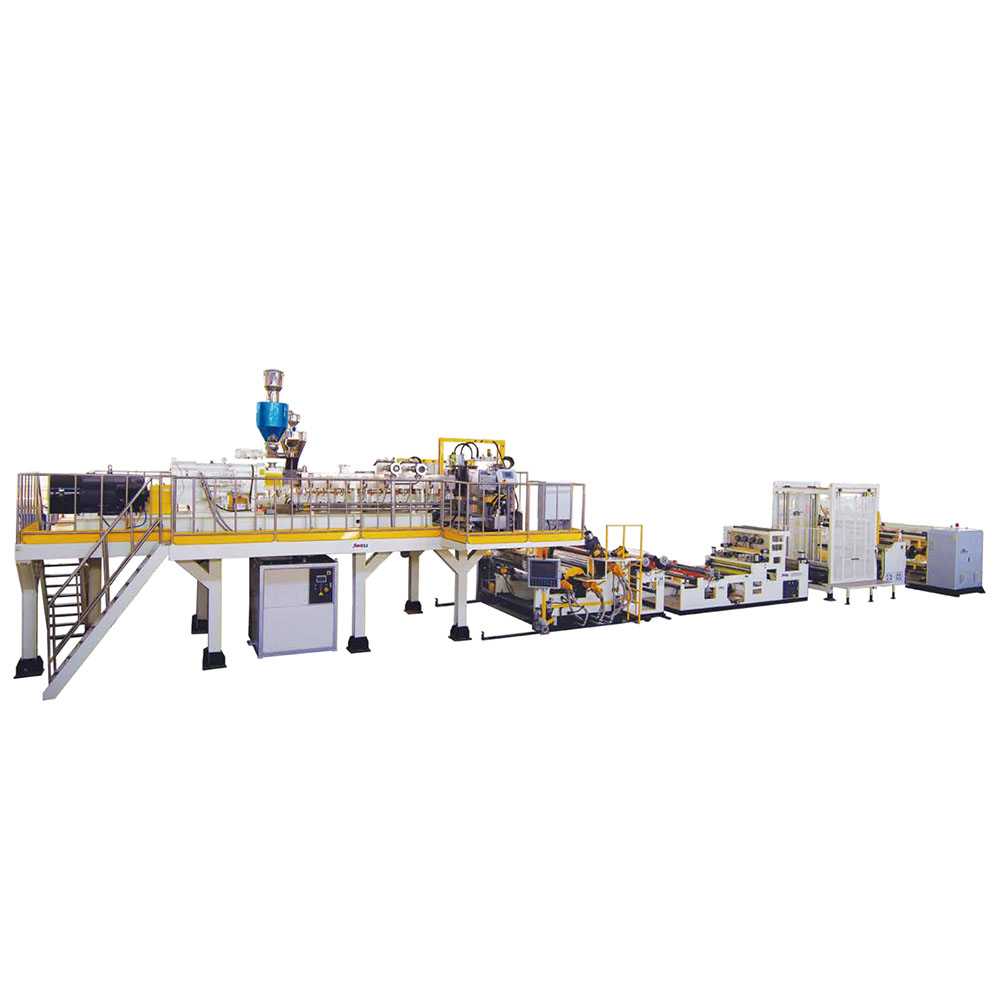

18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL

18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL Detail:

PVC corrugated board and Step-Roofing feature and application

● The fire protection performance is remarkable, difficult to burn. Anti-corossion, Acidproof, alkali, radiates quickly, high light- ing, logn life-span.

● Adopt special technology, bears the outdoor atmospheric insolation,the heat insulation performance is good, in the hot summer can provide compares the metal to use a tile more comfortable environment.

● The applicable scope is broad, the workshop, the warehouse, the vehicle shed, the agricultural market fair, the brattice, the wall body, the temporary store, the heat insulation awning and so on are suitable.

Main technical parameter

| Extruder Specificatior | $jz80/ 156&$J251/105 | $JZ80/156&Jw$50/30 | SJ292/188&JWS65/30 |

| Main motor power | 55kw | 55kw | 110kw |

| Products Width | 1140mm | 850mm | 880mm |

| capacity(Max.) | 300-40@kgh | 300-400kg/h | 400-600kgfh |

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for 18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL , The product will supply to all over the world, such as: French, Salt Lake City, Rotterdam, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of Standing in Domestic Markets, Walking into International Markets. We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

Write your message here and send it to us